Specialist Overview to Packaging Machine Repair for Optimal Performance

Specialist Overview to Packaging Machine Repair for Optimal Performance

Blog Article

Reliable Ways to Troubleshoot Common Issues in Product Packaging Equipment Procedure

In the world of manufacturing and production, making certain the seamless procedure of product packaging devices is paramount to keeping effectiveness and meeting due dates. Let's discover some effective strategies that can assist in swiftly resolving typical problems in product packaging device procedure.

Identifying Common Packaging Maker Problems

When repairing packaging equipment issues, it is crucial to precisely recognize common problems that might occur throughout the product packaging process. One typical trouble experienced in product packaging makers is improper sealing.

Furthermore, concerns with sensing units can interfere with the packaging process by stopping working to spot items or causing incorrectly. packaging machine repair. Electric problems, such as defective electrical wiring or power supply concerns, are also common wrongdoers behind product packaging machine failures. Recognizing and promptly attending to these common problems are necessary for maintaining the effectiveness and reliability of product packaging procedures. By identifying these issues at an early stage, operators can stop downtime, minimize item waste, and make sure the smooth performance of product packaging machinery.

Executing Regular Maintenance Checks

On a regular basis conducting detailed maintenance checks is necessary for ensuring the ideal efficiency and longevity of packaging equipments. Additionally, inspecting and adjusting setups related to temperature level, rate, and stress can aid keep the machine's effectiveness and precision.

In addition, conducting regular examinations of electrical connections and controls can aid prevent electrical malfunctions and make certain the safety of the maker drivers. Documenting maintenance activities and keeping in-depth documents of components replacements and repair work can help in tracking the maker's efficiency over time and determining any kind of recurring problems. Inevitably, an aggressive approach to routine maintenance checks is vital in maximizing the productivity and reliability of packaging devices.

Fixing Electric and Mechanical Issues

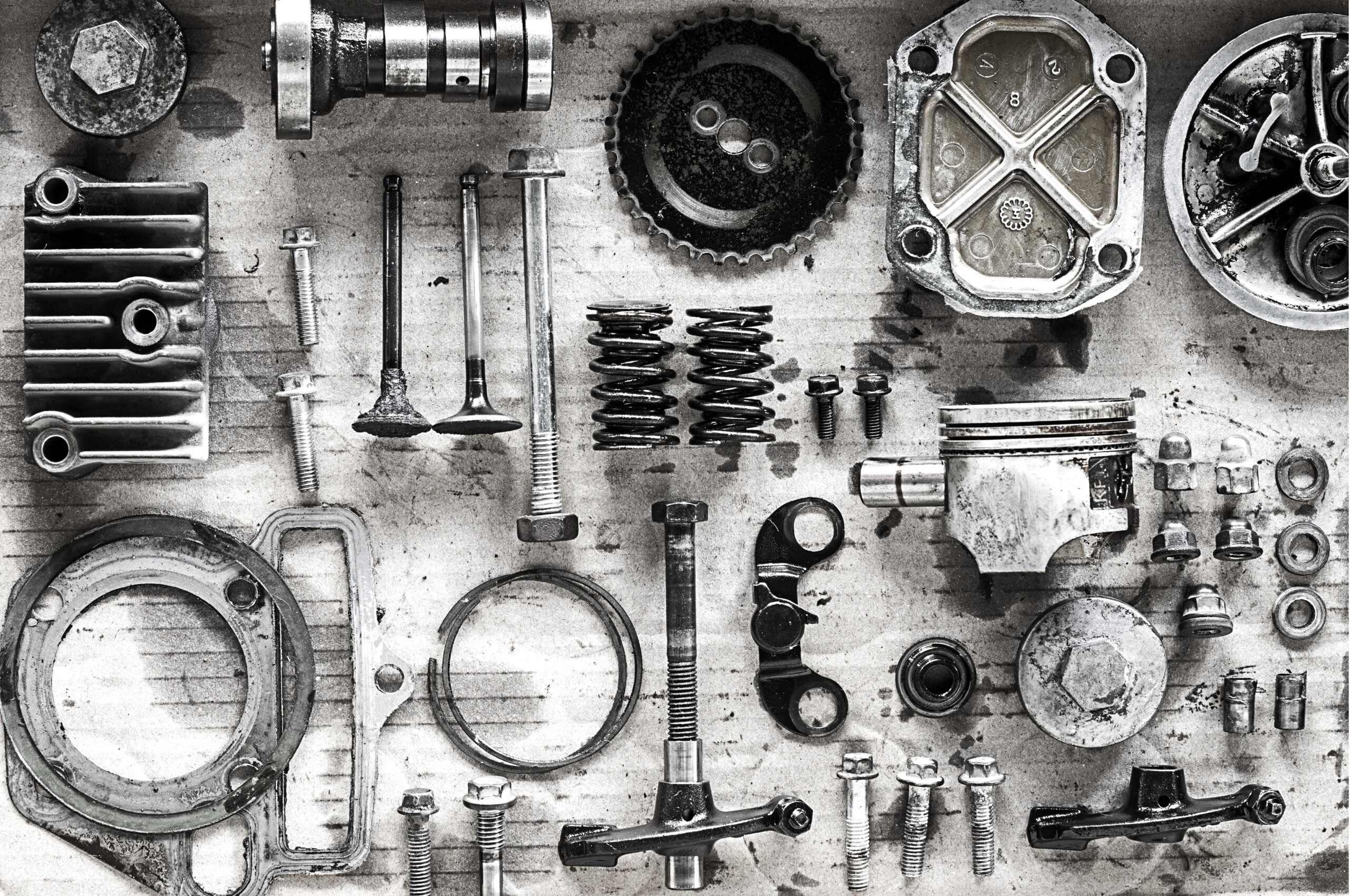

Reliable troubleshooting of mechanical and electric issues in packaging machines calls for an organized technique and a deep understanding of the maker's components and procedure. When encountering electrical concerns, beginning by inspecting source of power, connections, and control board for any type of visible damages or loose connections. Utilizing a multimeter can help recognize electric faults such as brief circuits or open circuits. In addition, checking sensors, actuators, and passes on for correct functionality is essential in diagnosing electric malfunctions precisely.

Lubrication of vital elements can stop friction-related issues and guarantee smooth device operation. Validating the placement of elements and changing stress where essential can remedy problems related to misalignments or irregular activities in the product packaging device.

Optimizing Device Settings for Effectiveness

To improve the total performance of product site link packaging machines, a critical facet involves fine-tuning and enhancing maker setups for maximum effectiveness and result uniformity. Correctly adjusted equipment setups can considerably affect the rate, precision, and quality of the packaging procedure. Regularly keeping track of and changing these maker setups based on the details requirements of the packaging materials and product can lead to boosted performance, lowered downtime, and improved overall output quality.

Executing Precautionary Upkeep Procedures

Applying preventative upkeep measures is crucial for guaranteeing the durability and ideal performance of packaging makers in commercial settings. Routine maintenance helps avoid unexpected failures, minimizes downtime, and inevitably saves time and money for companies. To efficiently execute preventive maintenance, develop a detailed upkeep image source timetable laying out jobs such as cleaning, lubricating, examining, and replacing used components. This routine ought to be followed faithfully by skilled maintenance personnel to make certain that the makers operate at peak efficiency.

In addition to scheduled maintenance, it is essential to maintain thorough documents of all upkeep tasks performed on the packaging machines. By prioritizing preventive maintenance, businesses can prolong the lifespan of their packaging machines, minimize disruptions in manufacturing, and keep regular item top quality.

Verdict

In conclusion, effective troubleshooting of usual concerns in product packaging device operation includes determining troubles, performing routine maintenance checks, fixing electrical and mechanical problems, enhancing equipment setups for efficiency, and carrying out precautionary upkeep measures. By complying Recommended Site with these steps, operators can make sure smooth and trusted procedure of product packaging equipments, decreasing downtime and optimizing efficiency.

When fixing packaging device problems, it is crucial to accurately recognize usual problems that may arise throughout the product packaging process.Effective troubleshooting of electrical and mechanical issues in packaging machines calls for an organized technique and a deep understanding of the device's components and procedure.To improve the overall efficiency of packaging machines, a crucial aspect entails fine-tuning and enhancing machine setups for maximum performance and outcome uniformity.Carrying out precautionary upkeep steps is essential for making certain the durability and optimal efficiency of packaging makers in industrial setups.In addition to set up maintenance, it is crucial to keep thorough documents of all maintenance tasks performed on the product packaging machines.

Report this page